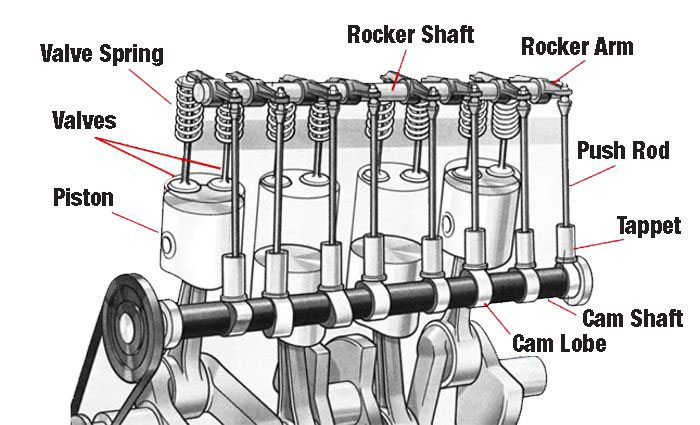

It could be your tappets. This is caused by your valve clearances getting bigger. This can happen for a variety of reasons.

1. Head gasket replaced and/or the head skimmed.

2. Poorly adjusted valve clearances.

3. Valve seat recession.

4. Bent push rods.

Let’s take each one and explain them simply.

1. If you have to lift the cylinder head for any reason the gap between the head and the block will change (head gaskets vary in thickness) this will upset valve clearance. If the head has been skimmed the head is now closer to the block and the valve clearance will be closed up, too tight. This will also increase your compression ratio.

2. The previous owner may never have set the clearances right, or the rocker shaft may have been removed for some reason and was not torqued down correctly, or the rockers and/or shaft may be worn. Or the tappets may be loose and/or worn out through lack of oil or contaminated oil.

3. This is the expensive one. If the car was manufactured to run on leaded petrol and is now running on unleaded petrol an additive should have been used with each petrol fill. I have always used Millers Octane Booster (no they are not paying me to type this) and have never had a problem. If no additive was used then it is possible the lack of lead substitute which is used as a lubricant has caused the valve seats to be pounded into the head thus upsetting the valve clearance. New valve seats especially inlet valve seats will need to be replaced. So off with its head. Over revving and/or using high revs for long periods of time can add to this problem. However if the cylinder head is aluminium then this should not happen as the valve seats would been hardened anyway when inserted into the head. Also it is said that the older the car the seats will have hardened up due to use/high mileage and should be okay.

4. Bent push rods can happen for a variety of reasons, over-revving, timing chain slipping, over tight valve clearances, mix up in re-fitting push rods when rebuilding an engine, head skimming and/or new head gasket etc.

If your valve clearances are too loose the engine will lack power, will rattle and will eventually harm the working surfaces of the valve seats and valve stems etc. If they are too tight, or in fact no clearances at all, there is a high risk of burning the valve seats leading to loss of compression or you may even smack a valve off the top of a piston or two and will cost you money and down time.

Anyway how do we go about setting valve clearances?

Firstly, you need to know what your valve clearances are and whether they should be adjusted with the engine hot or cold. There has to be a small clearance between the top of the valve stem and rocker to ensure that the valves will be fully closed at some stage during the running of the engine. Clearance is set when the valve is fully closed. This can be hard to judge but the trick with 4 cylinder engines is the “Rule of 9”.

Remove all the spark plugs making it easier to turn the engine by hand or with a socket on the crankshaft. Turn the engine over until valve number one is fully open, rocker loose. Subtract one from nine and adjust number eight, with two open (rocker loose) adjust number seven and so on.

The “Rule of 13” applies to most 6 cylinder engines, subtract the open valve from 13 to see which one to adjust. To adjust slip the correct feeler gauge blade under the rocker and the top of the valve stem. Slacken the lock nut and using a screwdriver either turn the stud clockwise to tighten the gap or anti-clockwise to loosen the gap. When the feeler gauge is just nipped (drags to remove it) hold the stud tight and lock the lock nut. The feeler gauge should be tight to insert, but it should be possible to slide it through with gentle force. When done rotate the engine by hand a few times and recheck the clearances. Exhaust valves can have a bigger clearance because of expansion due to exhaust heat.

Overhead camshaft engines such as Imps use shims to make the clearance between the valve stem and the camshaft. The shim usually sits in the bucket on top of the valve stem. This is a much trickier job to tackle especially if you do not have access to a bucketful of shims. I spent many an hour with an oilstone honing off a thou here and a thou there to get valve settings correct.

The more modern classic cars might have hydraulic tappets which need no adjusting. The clearance is obtained by oil pressure. However they can fail due to lack of oil and oil filter changes and become bunged up with crud. They can be cleaned out by soaking in petrol or in fact good old WD40, but they may have to be replaced.

A word of warning if using an Octane Booster do not mix the different types/makes. Make sure you stick with one type. Mixing different types/makes can cause explosive results.

BARRY BURKE